Demolition and reconstruction of the reverse arch in reinforced concrete of the Cassia – monte mario railroad tunnel, after consolidating and waterproofing the underlying terrain by freezing.

2004 | 2013

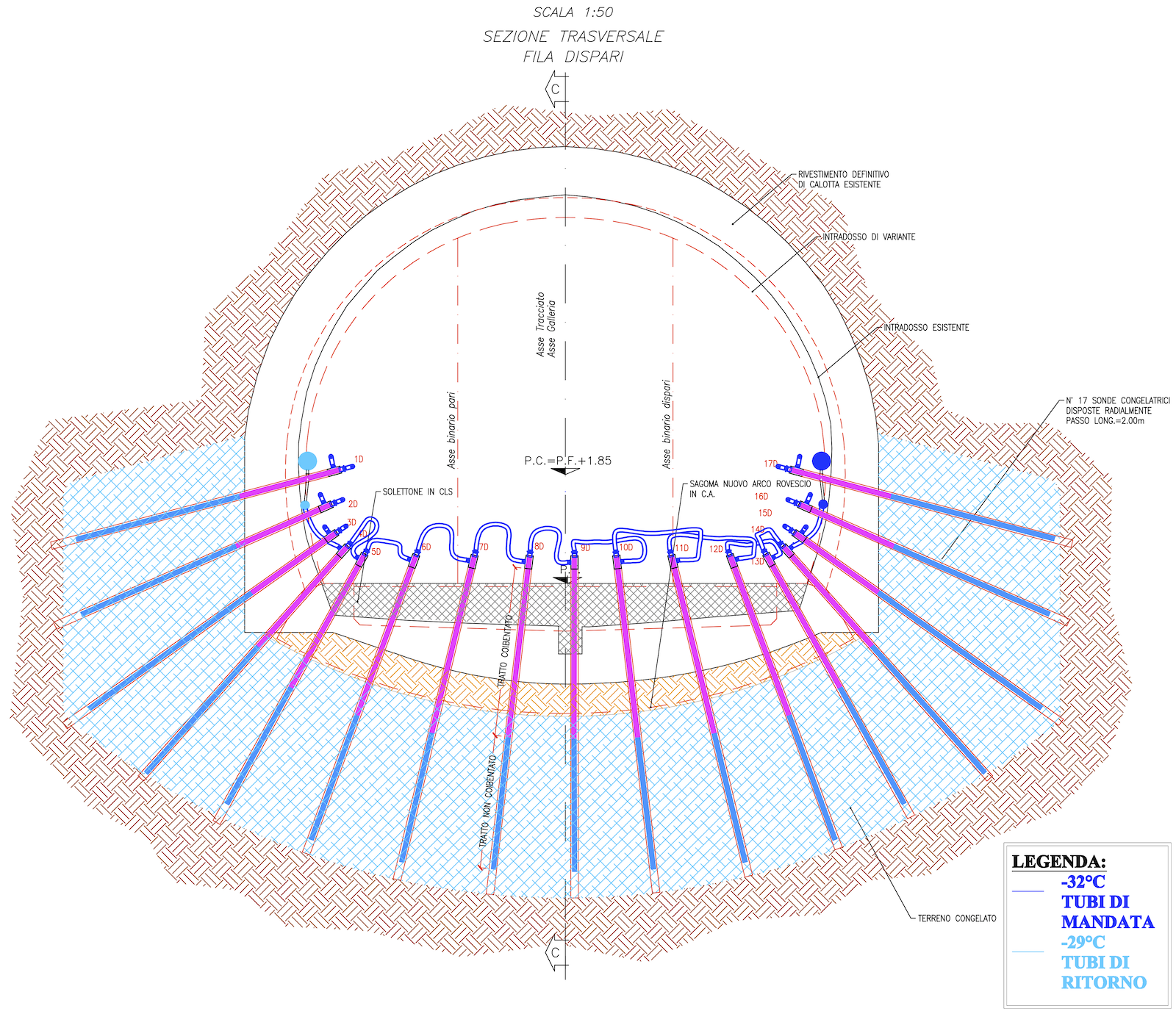

The work is part of the project for the consolidation and reshapeing of the Cassia-Monte Mario Gallery, which in turn is included in the wider intervention called “Gronda Merci di Roma”, a strategic infrastructure project of national interest for Italy. The history of the gallery is very long. The project for its construction dates back to the early 1900s. The construction of the tunnel was suspended due to the Second World War and, subsequently, due to the loss of interest in the project. This interest was awakened on the eve of the 1990 World Cup. The tunnel was completed and an underground station was opened (Stazione di Olimpico-Farnesina) serving passengers on their way from/to Olympic stadium. The tunnel was then abandoned in the ‘90s following structural problems that caused the inverted arch to be raised. With the new millennium, interest in the tunnel has reawakened because the opening of the railway section on which it is located would allow the completion of the railway ring of Rome and lighten the traffic of trains on the eastern section. It was decided to intervene to solve the structural problems and to reshape the tunnel to adapt it to the new regulations. On November 2004, during those works, in fase of demolition and reconstruction of the invert arch an unexpected event occurred: a high pressure water inflow transported thousands of cubic meters of fine material into the tunnel triggering damage at the tunnel but also consequent surface effects due to drainage and solid transport. The works underwent a new stop to define how to proceed. After examining the various possible ways, freezing was chosen. This method consists in freezing water in the pores of the ground and it returns satisfactory results in geotechnical contexts such as those present in the contour of this tunnel. Once the optimal operating temperature has been reached, we have a completely waterproof screen and the mechanical resistance necessary to proceed safely with the ROMA (Italy) | Cassia-M.Mario Railway Tunnel demolition/reconstruction, even if for a limited time. Of course, the best hydraulic and static performance has a cost in terms of technological complexity, with works that must be carefully planned in terms of time and performance, considering that the costs, as well as the potential of the equipment installed, are proportional to the temperature to be reached and the duration of the freezing and maintenance phases during the demolition/reconstruction of the inverted arch. In our case, in particular, the indirect method (calcium chloride brine) was adopted instead of the direct mode (liquid nitrogen) because, although it requires longer times, it has lower costs for materials and exposes workers to lower risks because operating temperatures are higher. Naturally, the choice was possible because the program of works in the gallery was compatible with the greater time required. The indirect method is defined as such because the ground is cooled by means of a double heat exchange. The first exchange takes place inside the refrigeration unit in which the brine which flows in a closed circuit, is cooled. The second exchange takes place in the freezing probes: the cold brine flows inside, subtracting heat from the ground and exiting to return to the refrigeration unit. A typical refrigeration plant consists of four main elements: evaporator, compressor, condenser and laminator. In the case described, as many as 8 compressor units with two evaporation towers were used, with a total power of 500 kW. All systems were installed inside the tunnel, near the work zone; only the evaporation towers were positioned outside, at the distance of over one kilometer from the area to freeze. The working temperatures were as follows: • about -30°C the brine temperature, • 3÷4°C the Δt between outgoing and returning of brine to the refrigeration unit, • 0°C positioned on theoretical excavation profile, • -10°C the average soil temperature at the target. After the preparation of necessary equipments and the installation of all related accessories, the freezing was started up in the first four sections of 12 meters. The soil temperature was constantly monitored with thermometric probes installed in the mass to be frozen. Once the target temperature was reached the freezing were moved to the next free field and the demolition and reconstruction of the inverted arch proceeded. With this production cycle combined with work shifts that covered 24 hours for 7 days a week made possible to obtain production of 12 m per week of new inverted arch. These are the main stages of processing: • installation of stand pipes in the existing inverted arch and subsequent sheaths positioning (micropiles). This was done with the aid of preventers in the holes to guard against water inflow, • preparation in each field of 12 m with 210 radiating probes housed in the sheaths, arranged in a quincunx pattern with a spacing of 1x1 m and suitably insulated to obtain a thickness of about 3 m of frozen terrain, • similar preparation of the necessary thermometric probes, equipped with suitable control thermocouples, • freezing for a time variable from 21 to 28 days per field, • detachment of freezing system and demolition by slabs of 4 m, • installation of reinforcement and pouring of the new inverted arch. The acquired data were processed in specific daily reports of the temperature curves, according to the distance between thermometric and freezer probes. For the validation of the technical choices, the characteristics of the soil were verified by corings before and after freezing. Tunnel convergence readings and stress measurements on the new structure were performed during the works as well as surface monitoring of the structures and soil over the frozen zone.