Construction of 3 diaphragms with Jet Grouting technology for protection of the excavation of two tunnels under 5 existing lines of

the New York subway system.

1995 | 1997

The works are part of the 63rd Street Line Connection Project of the NYCT master plan to extend subway service and resolve congestion on the existing New York City subway lines to connect Manhattan and Queens.

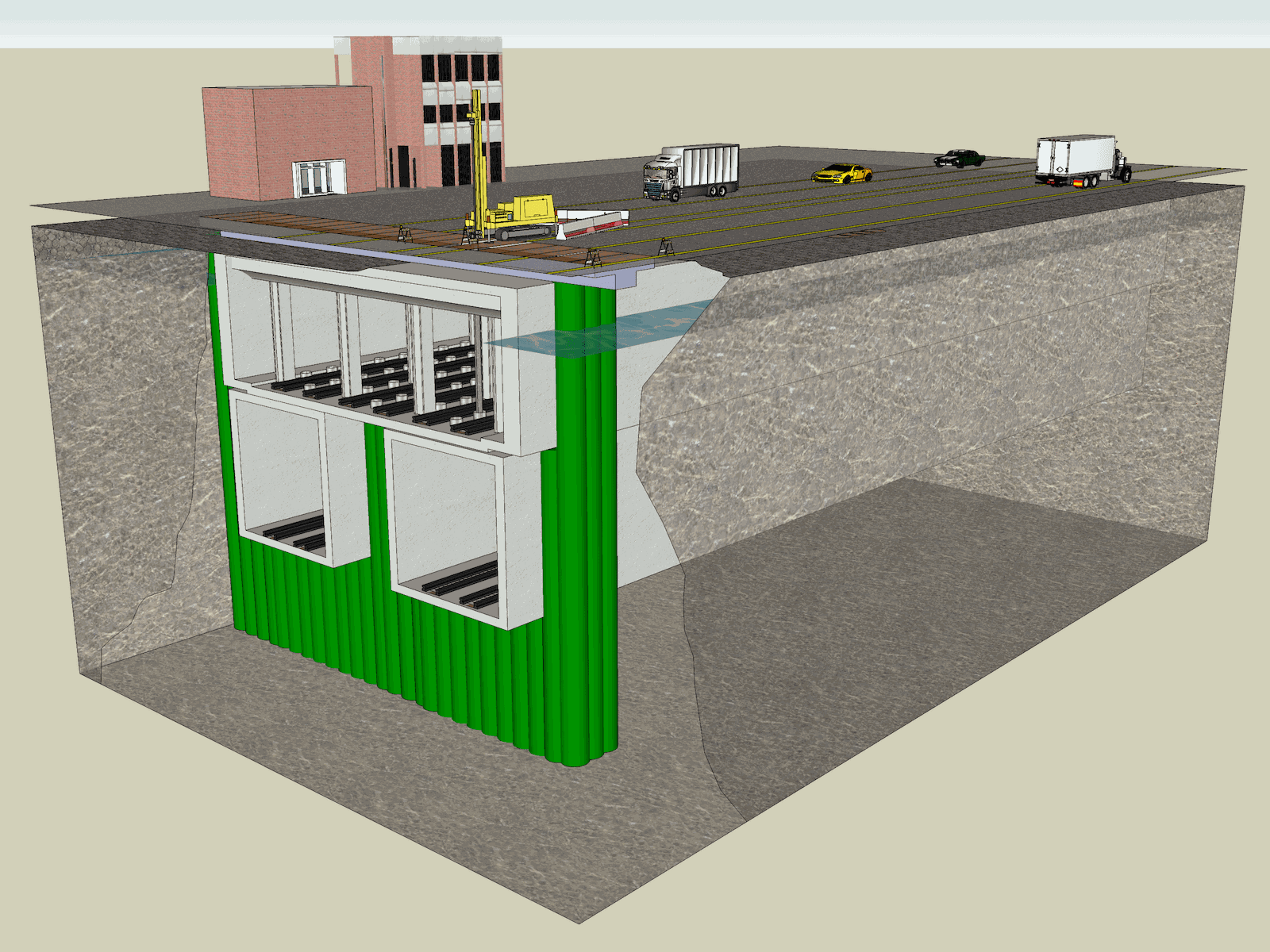

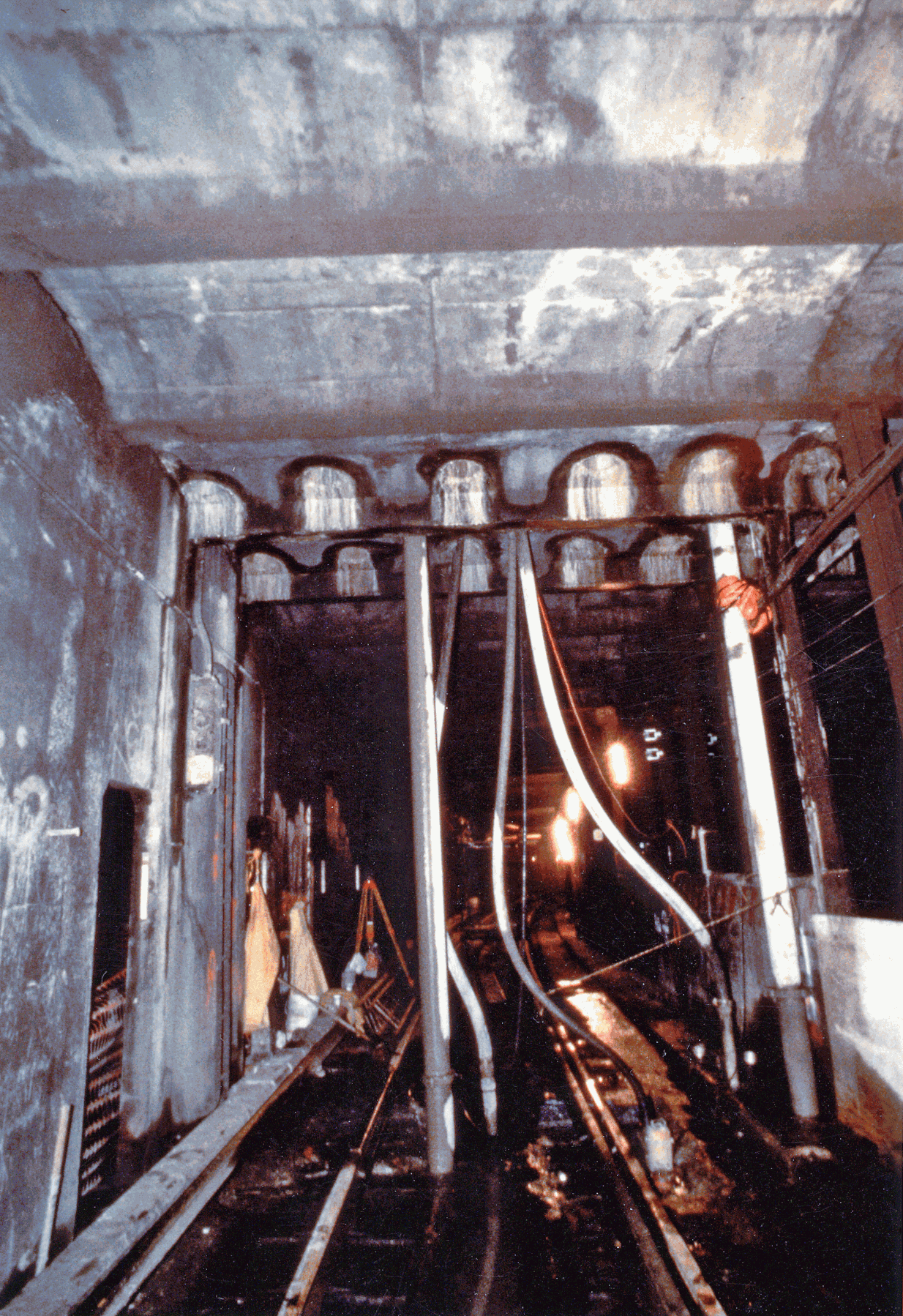

The realization of the project involved the construction of a new tunnel 1600 ft long under the existing underground lines and kept in service. In order to do this, the groundwater level had to be lowered. A watertight enclosure was therefore necessary to allow dewatering inside, where the tunnels were built, minimizing the withdrawal of the water table outside the enclosure. This enclosure was formed by cutoff walls consist of a combination of slurry diaphragm walls and four jet grouted walls. The jet grouting was used in areas where conventional slurry walls could not be constructed due to the presence of existing subsurface and surface structures and utilities. Furthermore NYCTA, imposed specifications including performing works from outside, prohibition to interfere with road traffic, rail traffic and the circulation of subway trains and limits on the height for certain stages of the work.

The work was complicated by the variability and heterogeneity of the subsoil, in fact the project site rests on a metamorphic bedrock, covered by glacial and postglacial deposits. The stratification of these deposits is complex and shows significant variations in thickness and distribution. This heterogeneity is typical of the glacial deposits found in the terminal part of the moraines.

General subsurface profile at the project site consists of most superficial miscellaneous fill consisting of a heterogeneous mixture made up sands, silt, gravel, brick fragments, wood, metal, and other building rubble. Peats and organic silts are encountered randomly underlies this layer. Going down there are mixed glacial deposits composed of loose to medium dense sand, very fine sand, silt and clay where boulders and cobbles are also commonly encountered. The bedrock ranging from totally weathered to slightly fractured to sound granite gneiss to schistose gneiss with occasional quartz pegmatite.

The work we carried out consisted precisely in creating three of the four walls of columns. For a total length of 510 ft (155m) of walls approximately 550 individual columns were installed which extended from a depth of approximately 115ft (35m) to the ground surface. Each wall was built with three rows of overlapping columns for a total wall thickness of between 7 and 8ft (213 ÷ 244cm). A minimum overlapping thickness of 12in (30cm) was required between adjacent columns.

The construction of the three diaphragms was made with three parallel rows of columns arranged in a quincunx with variable spacing from 2ft 11in (75cm) to 3ft (91cm) and using the Jet Grouting system PS3 triple-fluid technology (air, water and grout) using a bottom-up installation procedure.

55 control holes were made with continuous coring during the execution of the works - on average every 10ft (3m) of wall - and were used to verify the effectiveness of the treatments carried out. They returned average compressive strength values of about 1450 psi (10 MPa) and coefficient of permeability (K) values less than 1x10-8 m/sec while the excavation of the columns revealed diameters between 5ft (200cm) and 6.5ft (250cm) and wall thicknesses up to 8.25 ft (250 cm).

A continuous monitoring of Jet Grouting parameters using PRS3 real time data collection system and the vertical measurement at each grout column using the inclinometer Pacchiosi Model 600G were provided as well as an extensive verification and field test prior the production work.