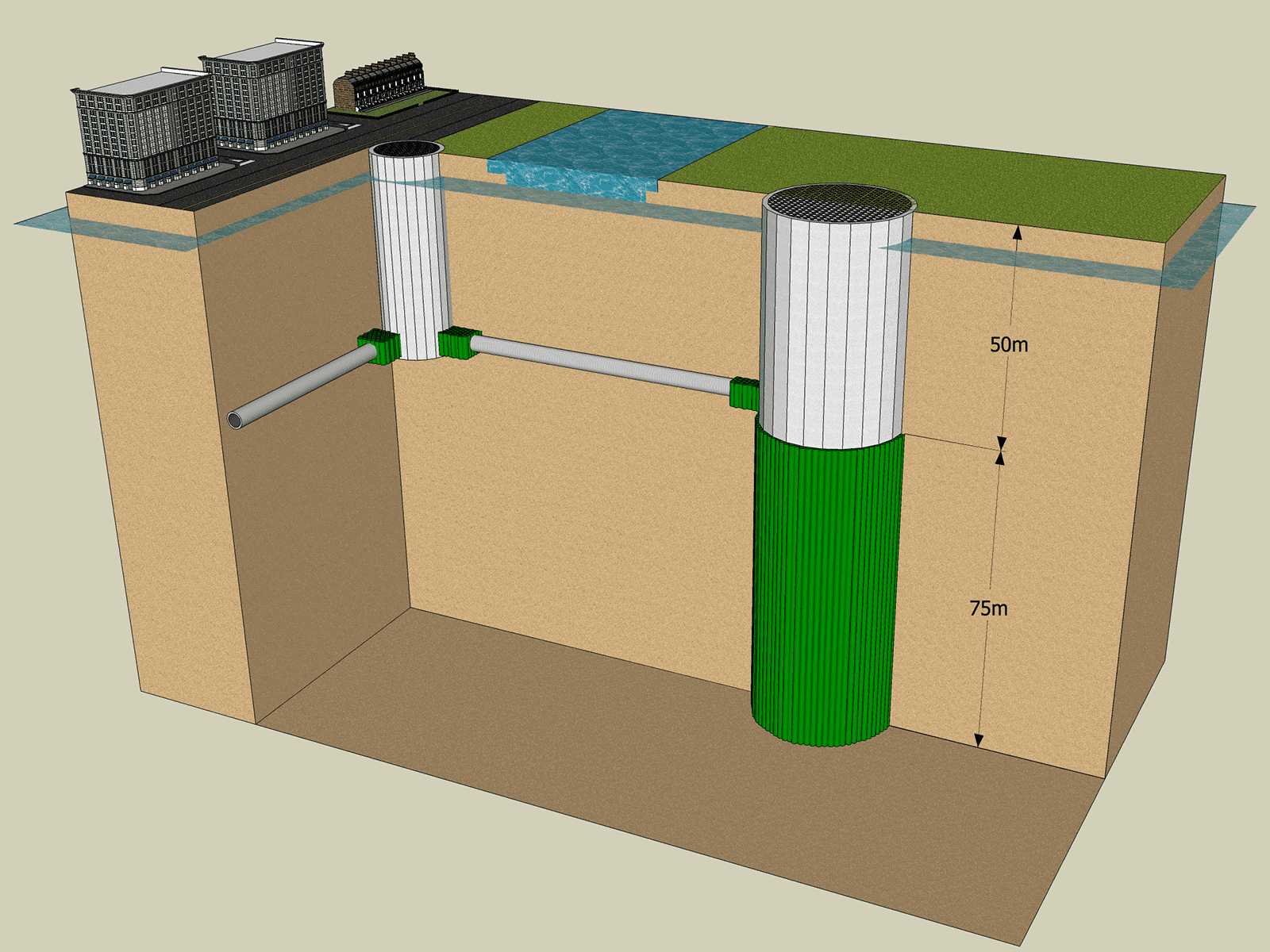

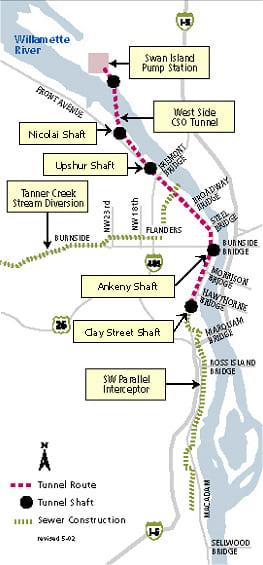

The “Combined Sewer” is a mixed sewer system that uses the same culverts for waste and white waters. The system required expansion and integration with a new large diameter sewer pipe. This was the purpose of the project “West Side Big Pipe” which involved the construction of a 14ft [4.25m] diameter culvert and approximately 3.5mi [5.63km] long, between Clay Street (Clay Shaft) and the Swan Island Pump Station Shaft and which runs along the west side near the Broadway, Steel and Burnside bridges.

2003 | 2004

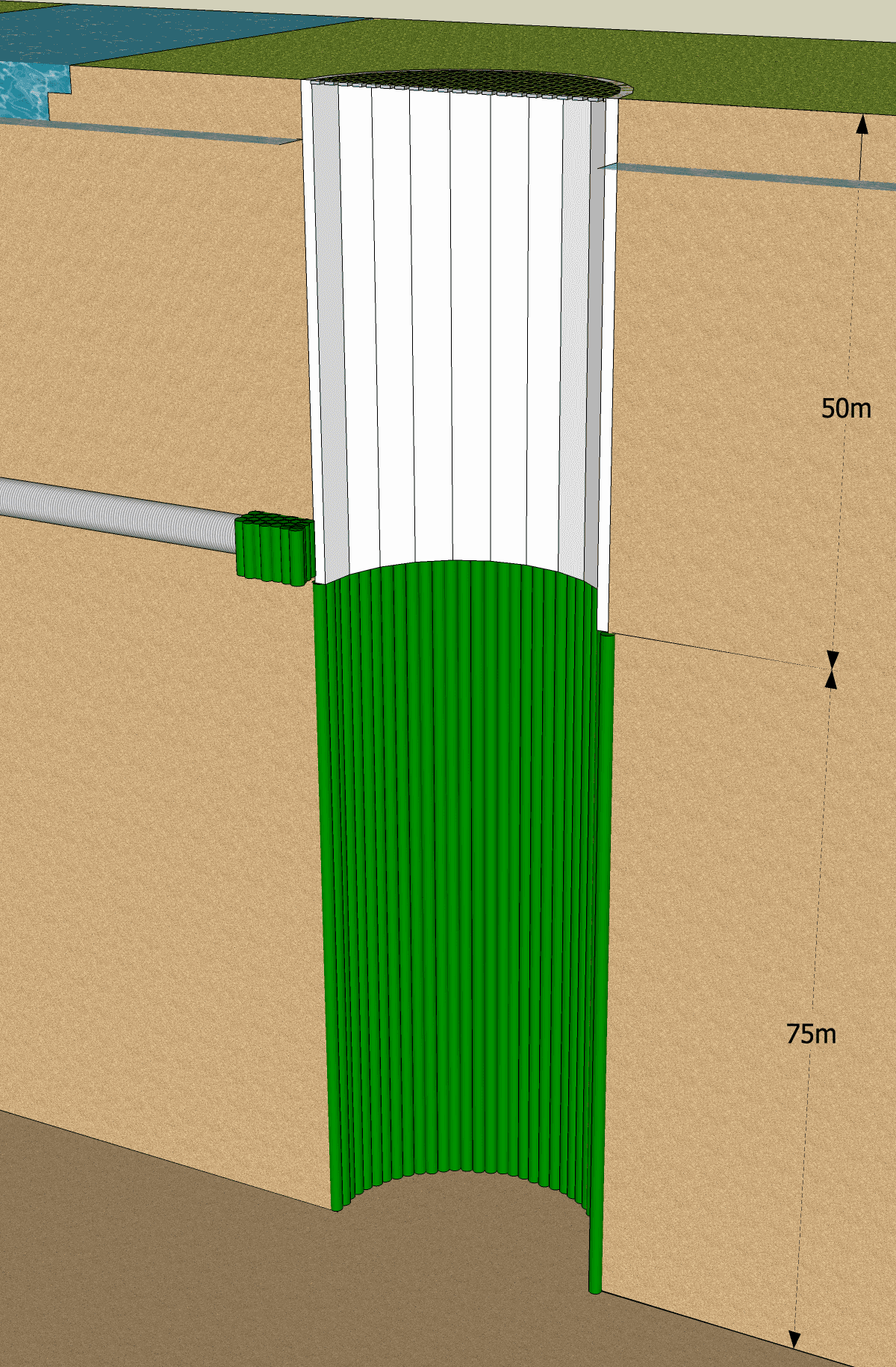

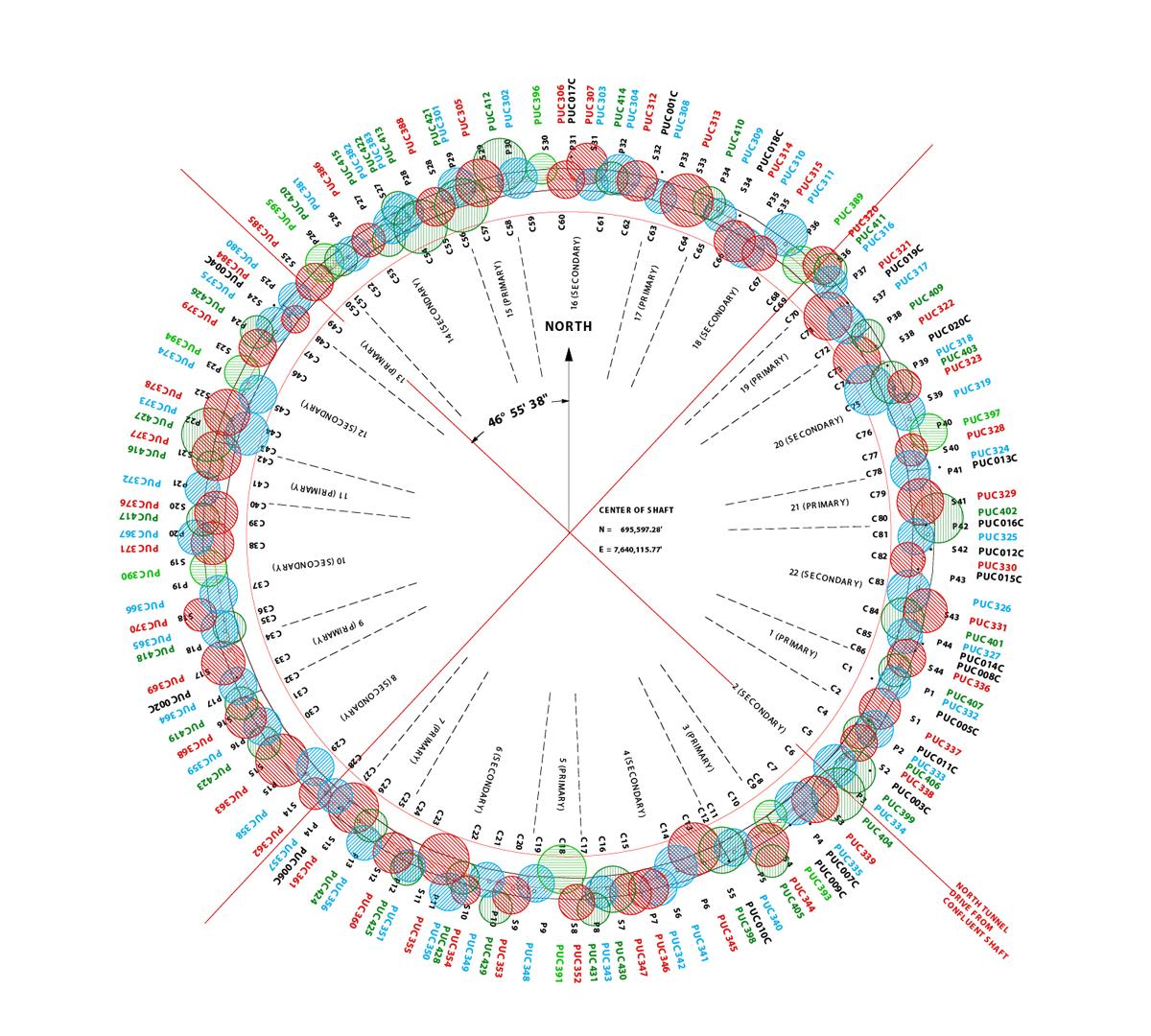

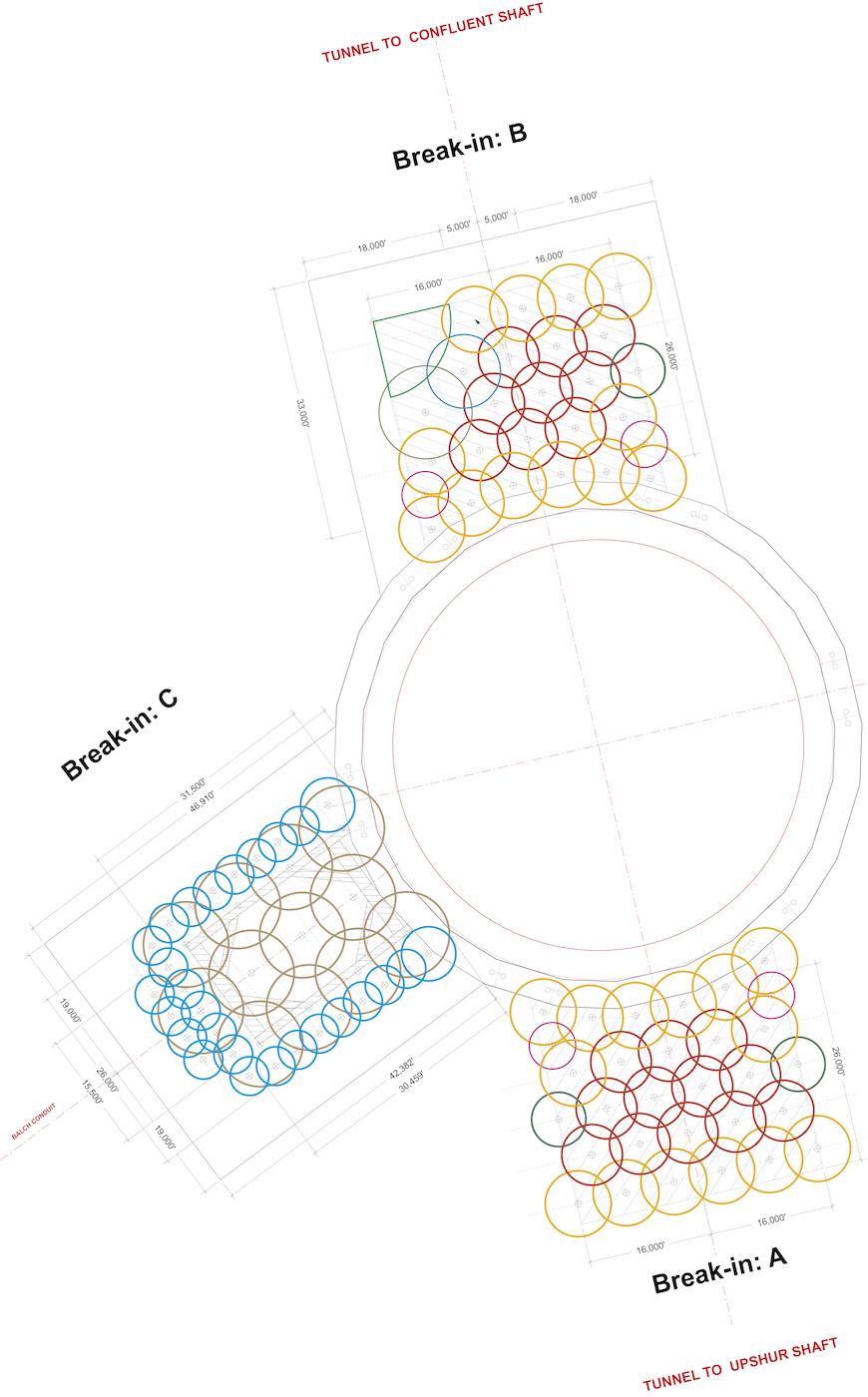

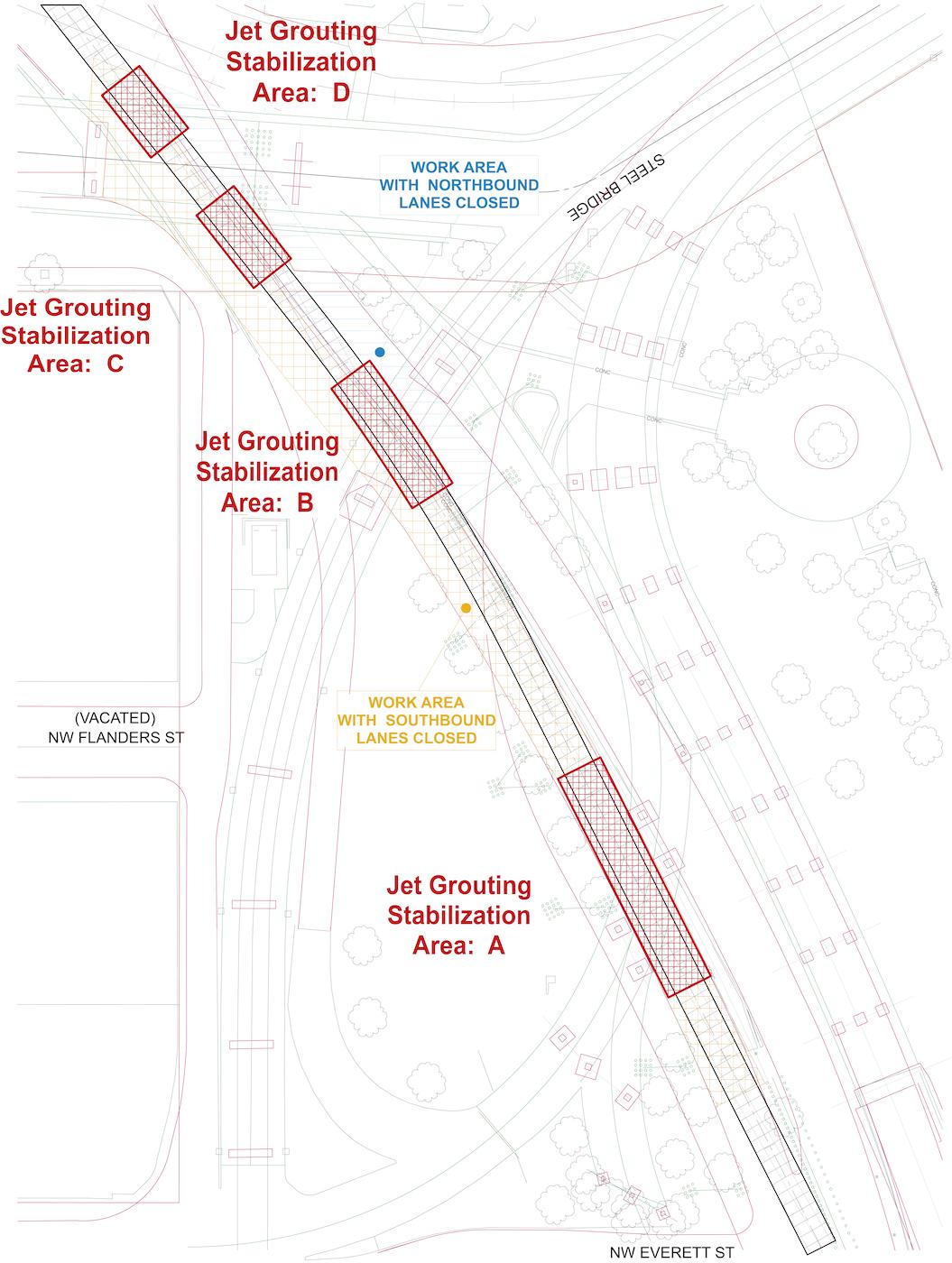

In the Willamette River Combined Sewer Overflow Control project, Jet Grouting treatments were aimed at creating cut-off wall under slurry wall, consolidate soil in the TBM break-in / break-out areas adjacent the shafts and, more generally, stabilize ground. The treated soils are different and form a typical sequence of four layers. An alluvial surface layer, formed by deposits of the Willamette River, composed of silty sand and silts. Below this, a layer of glacial and fluvio-glacial origin and, subsequently, a sedimentary deposit named “Troutdale Formation” composed of a conglomerate, coarse-grained sandstone and a siltstone. Lastly, a base layer composed of weathered basalt. The project was divided into several different work sites by position, type and depth of intervention: Nicolai Shaft, Confluent Shaft on Swan Island, the areas close to Steel, Burnside and Broadway bridges. To complete the interventions, about 650 columns of various diameters - from 6.5ft [2m] up to 13ft [4m] - were made at variable drilling depths between 33ft [10m] and 410ft [125m]. Given the depths reached and the nature of the soils, the greatest difficulties encountered were respecting the limit of deviation from the vertical and the danger of grounding, both aggravated by the presence of boulders. All Jet Grouting treatments were installed using a triple-fluid technology PS3 (air, water and grout) and bottom-up installation procedure. For each one were realized continuous monitoring and recording of Jet Grouting parameters using PRS3 real time data collection system and vertical measurement at each grout column were provided as well as preliminary extensive verification and field test.