2001 | 2002

The Diavik Diamonds Project is a project for the construction of an open-air diamond mine, constructed as a joint venture by the British company DDMI (60%) and the Canadian Aber Diamond Mines (40%). The deposit was discovered under the waters of Lac de Gras, a large lake located in the Northwest Territories of Canada, about 190mi (300km) northeast of the city of Yellowknife. It's an inhospitable area characterized by lakes, uninhabited islands and a prohibitive climate with temperatures that reach -58°F (-50°C) in the winter and +14°F (+10°C) in the summer. The mine can only be reached by air or, in the coldest months, between January and March, along an ice road. on the largest of the islands that occupy the lake a fully autonomous camp has been built, capable of sheltering up to 1000 people, complete with dormitories, cafeterias, offices, laboratories, workshops and an airport.

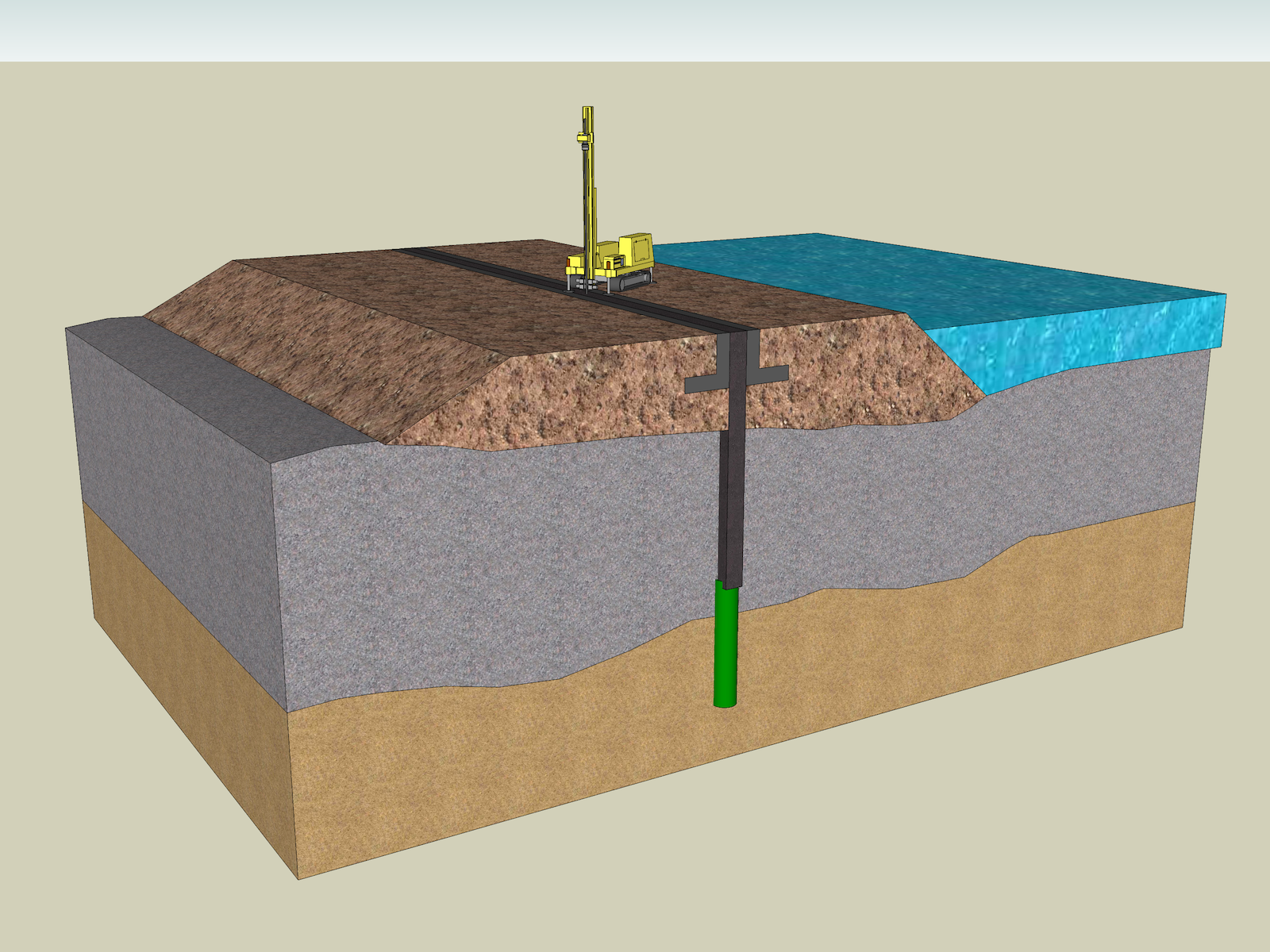

To make the bottom in the extraction area accessible, the lake had to be drained. To do this, the project involved the construction of a dam and a waterproof plastic diaphragm to separate the area and then drain the basin. The realization of the diaphragm is the part of the project that we have been to carry out.

Considering the extreme weather conditions, the work was performed using different methods at different times of the year. If during the summer period equipments were able to works outdoors, during the winter (November to May) the equipment had to work in heated environments. Drilling machines were protected by mobile sheds while the mixing and pumping machine were installed in fixed insulated structures; the water-air-cement lines were also completely insulated and heated.

The treatment had to be carried out through the body of the dam and the underlying moraine until to reach the bedrock.

Nature of the soils was quite uniform much less their composition. Superficial layer - the dam body - with thickness from 10 to 100ft (3 to 30m) was built from granite material quarried at the site and it had variable granulometry from sand to large diameter cobbles. The fluvio-glacial and moraine layer with variable thickness from 6 to 50ft (from 2 to 15m) with granulometry from silt to gravel with cobbles and boulders.

The Jet Grouting technique was used to complete the waterproof screen and joint the diaphragm to the rocky substrate. The work was done using the Pacchiosi PS3 Triple System preceded by a field test performed directly on the dam, to optimize the drilling and injection parameters. Columns with diameters between 1.24 m and 1.60 m were made with a pitch of 0.75 m to achieve the overlap of more than 0.8m which is the minimum required waterproof screen thickness.

At the end of each drilling, the verticality measurement was performed along the entire length of the hole with the Pacchiosi model P401 inclinometer to verify that the maximum design deviation was respected

As per the client's specifications, the samples taken by coring had to have a permeability coefficient K lower than 10^ -8 m/sec in at least 80% of cases and in any case lower than 10^ -7 m/sec and a compressive strength between 116 and 290 psi (0.8 and 2 MPa).